- Products & Materials

-

-

-

Product Families

-

-

-

-

Products & Materials

We collaborate closely with your team to deliver application-specific plastic compounds and accelerate your time to market.

-

-

- Industries

-

-

Solutions for Your Industry

We work with manufacturers in high-stakes industries like healthcare, automotive, electronics and building materials where performance, compliance and reliability are essential.

-

- Building & ConstructionMaterials that withstand weather, UV, and structural demands in outdoor and load-bearing applications.

- TransportationEngineered compounds built for durability, compliance, and reliability across vehicles, aircraft, ag, and power sports.

- FibersSoftness, strength, and stability for nonwovens, synthetic turf, hygiene products, and performance textiles.

-

- PackagingCustom masterbatches and additives for barrier performance, clarity, and sustainable packaging formats.

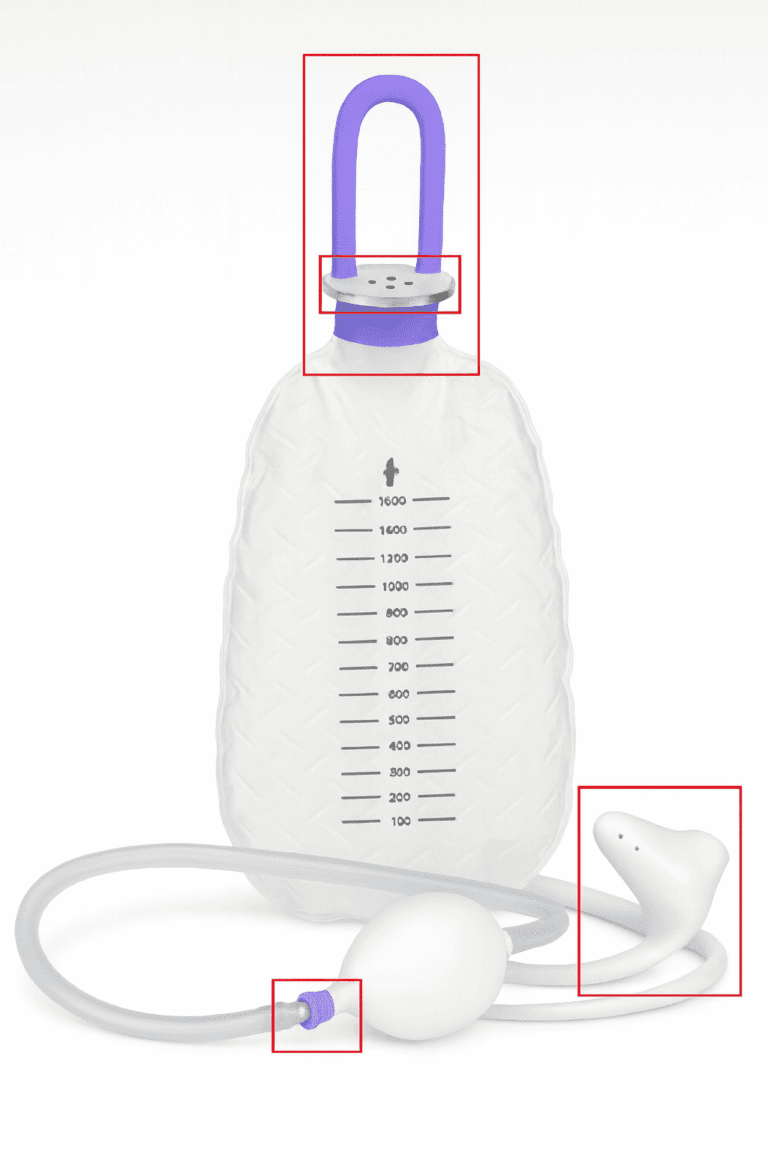

- HealthcareMedical-grade materials engineered for biocompatibility, sterilization, and global regulatory compliance.

- ElectronicsFlame-retardant, antistatic, and heat-resistant compounds for electronic housings and sensitive components.

-

-

- Services & Expertise

-

-

Services & Expertise

Americhem isn’t just a compounder, we are a full-service extension of your engineering, marketing, and product development teams.

-

-

- About

-

-

About Americhem

For more than eight decades, Americham has been your trusted global partner in designing and manufacturing polymer solutions.

-

-

- Talk to an Expert