COMPOUND PERFORMANCE YOU CAN COUNT ON

Americhem customers expect the very best quality and innovative solutions from us. Beyond our technical achievements in performance compounding, you’ll benefit from material expertise, advice and support from initial design through final production. Our thermoplastic compound products are carefully engineered to match specific processing techniques and application requirements. We are a recognized market leader in the performance polymer industry, having developed thousands of formulations that redefine material behavior. To ensure consistent quality and help our customers achieve compliance with standards such as UL, FDA, NSF, ISO 10993, IATF 16949, REACH and RoHS, we employ state-of-the-art technologies and perform extensive testing, analysis and documentation. It’s all part of our total commitment to protecting your brand and advancing your success.

TURNING VERSATILE PLASTICS INTO HIGH-PERFORMANCE POLYMERS

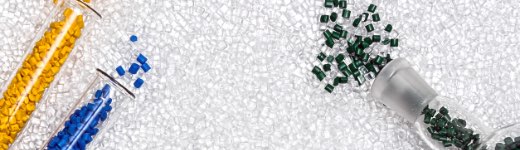

Thermoplastic materials are always in high demand because of their versatility. They are used across a wide variety of industries and applications worldwide. Americhem takes base resins like PVC, SEBS and polypropylene, and makes them better. Through careful analysis and selection, we mix these resins with different ratios and combinations of product additives to create high-performance thermoplastics with desired structural integrity, impact strength, flame retardance, chemical resistance, UV resistance and other enhanced physical properties.

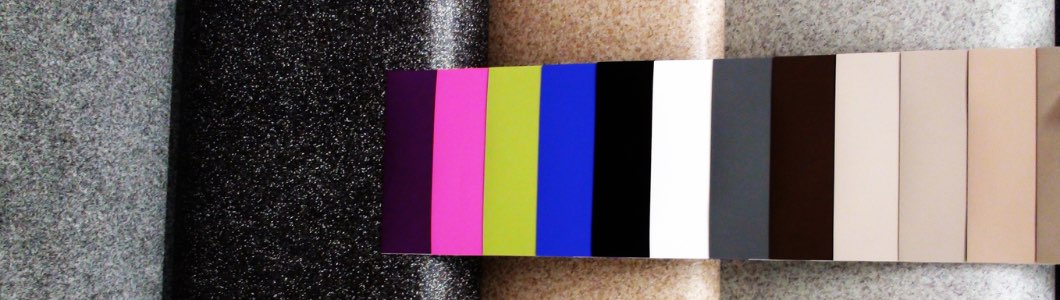

Need to achieve exact color duplication with excellent dispersion? Our thermoplastic compounding capabilities include color additive formulas that will produce a consistent quality appearance that endures for the life of your product.

No matter how challenging the application, our material experts will arrive at the right combination of materials to deliver a durable thermoplastic compound that helps strengthen your position in the marketplace.

COMPETITIVE ADVANTAGES THAT ADD UP

Americhem’s thermoplastic compounds and polymeric alloys provide processing ease, resulting in less waste during manufacturing. Offered as standard pellets, our compounds are suitable for injection molding, extrusion and blow-molding production methods. They can feature a high recycled content to support sustainable manufacturing practices and recycling by the end user.

We work diligently with our customers to make shared decisions that facilitate collaboration and rapid turnaround times. When it comes to made-to-order performance polymers, Americhem is a recognized development partner of major OEMs and their suppliers. Leverage our extensive knowledge and experience to reach your project’s quality, efficiency and cost targets.

Ready to compound your success with performance compounding?

Don’t wait any longer! Get in touch with our team now so we can directly answer your questions, help you solve a problem, or just better understand what Americhem does as a compound and masterbatch manufacturer.

VIRTUALLY LIMITLESS DESIGN POSSIBILITIES

When you work with Americhem, you gain access to a comprehensive selection of raw materials from trusted supply partners. We’ll work with you to determine your most pressing needs and develop a unique thermoplastic compound formula that lets you produce the best possible version of your product or component. Our color, additive, filler and impact modifiers are chosen to enhance specific properties and achieve limitless design and performance combinations.

SOPHISTICATED SOLUTIONS FOR DIVERSE MARKETS

Americhem’s thermoplastic compounds add value and distinction across multiple markets. Don’t see your particular market segment here? We are always eager to investigate new opportunities and expand our offerings. Tell us about your application and we’ll find a way to enhance it.

OUR THERMOPLASTIC COMPOUND PRODUCT LINES

Sevrene® Thermoplastic Elastomers

These easy-to-process styrenic block copolymers can be customized for ideal stiffness, heat, ozone, compression set or UV-resistance, cost-reduction properties, and provide soft-touch haptics for enhanced end-use feel.

Cerberon™ Thermoplastic Elastomers

These alloyed elastomers combine plastic and small particles of vulcanized rubber to expand use temperature, ease processing, and provide good heat aging and flex fatigue.

Uravin™ Specialty Alloy

Ideal for high-use molded parts, this product family exhibits rubber-like properties with a dry, soft-touch feel similar to leather. It’s scuff-resistant, scratch-resistant and impact-resistant. Uravin™ offers excellent color retention when exposed to harsh temperatures and UV rays.

Flexovin™ Flexible Vinyl Compounds

These flexible compounds offer a strong balance of elastomeric properties and ease of coloring with the option of higher rigidity as needed.

V-Series Automotive Vinyl Compounds

Designed to meet the rigorous demands of interior automotive environments, this product line is suitable for extrusion and injection molding, and can be tailored for specific gloss and flow.

Trivin™ Series of rigid PVC Compounds and Alloys

This rigid and semi-rigid line of PVC compounds and alloys has superior flow characteristics that allow thin-wall parts to be produced via extrusion or injection molding.

eCap™ High-Performance Capstock

Available in a variety of material blends, these capstock compounds offer advanced weathering performance, dimensional stability and durability for decking, fencing, and other extruded building product applications.

Oleflex™ Thermoplastic Olefin

Developed as blends of polypropylene (hard phase) with an ethylene-propylene rubber (soft phase) compounded with additive packages, Oleflex™ provides a good cost and performance balance for flexible to semi-rigid parts.

BRINGING RELIABILITY AND COLOR TO THE FOREFRONT

Americhem has been at the forefront of thermoplastic compounding for decades with reliable solutions that extend beyond functional performance. We’ve earned our reputation as a premier color compound manufacturer, staying on top of ever-changing industry trends to offer precolored and custom color solutions that exceed our customer’s aesthetic expectations. Put the Americhem advantage in color technology to work for you!

STRETCH YOUR BOUNDARIES WITH AMERICHEM’S THERMOPLASTIC ELASTOMERS

Our performance compounding capabilities include a significant focus on thermoplastic elastomers. We specialize in working with elastomeric materials such as fPVC, TPE, TPV, TPU and TPO to produce rubber-like characteristics with over-molding, re-molding and recycling opportunities. Whether it’s stretch, grip, sealing, protection or comfort you need, we know how to optimize these performance polymers to deliver the greatest impact for your application.